Manufacturing Firm Gets Real-Time Insights Through A Data-Rich Dashboard

Manufacturing Firm Gets Real-Time Insights Through A Data-Rich Dashboard

- Technology : Pentaho

- Industry : Manufacturing

Business Objective

A leading manufacturing company aimed to overcome operational challenges and performance issues by harnessing real-time data from IoT devices within their production facilities. They sought a comprehensive analytics solution that could analyze the data, provide valuable insights on throughput, usage, and other critical computations, and enable data-driven decision-making. By analyzing real-time data, the client wanted to get visibility into production KPIs that enable some strategic real-time decision-making.

Solution

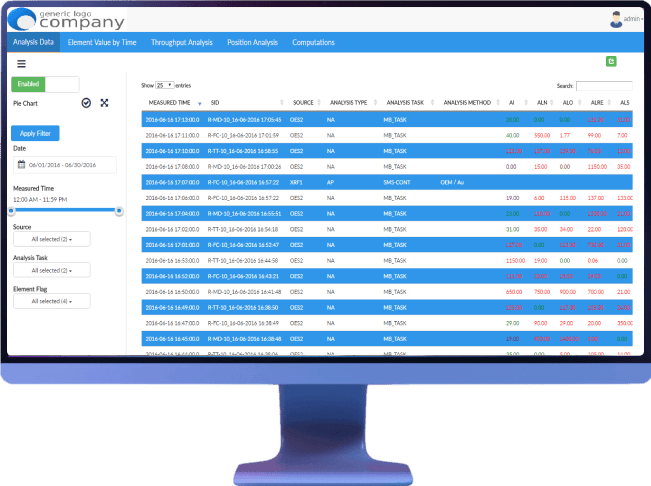

To address the manufacturing company’s challenges and achieve its objectives, we implemented a state-of-the-art real-time analytics dashboard. This solution seamlessly integrates with their existing IoT devices, allowing for the collection and analysis of real-time data from various sources within the production environment.

Pentaho, a powerful open-source data integration and business analytics platform, served as the foundation for the solution. Its robust capabilities enabled the extraction, transformation, and loading (ETL) processes necessary to acquire data from IoT devices. The data was then seamlessly transferred to Kibana, a user-friendly data visualization tool known for its rich features and intuitive interface.

Within the analytics dashboard, manufacturers gained access to a range of key performance indicators (KPIs), including throughput analysis, position analysis, Element Value by Time, and other important computations. The data was presented in real-time, allowing for immediate monitoring and analysis of critical manufacturing processes. By utilizing advanced algorithms and data models, the solution provided actionable insights and trend analysis, empowering decision-makers to make informed choices promptly. It also includes role-based access to data to improve security and reduce the risk of data breaches.

Result

By adopting this well-designed and complete analytics solution for the manufacturing industry, the company realized numerous benefits such as improved operational visibility, efficient resource allocation, and proactive maintenance.

The client successfully overcame the challenges of operational efficiency and optimization by using this easy-to-understand and easy-to-use complete analytics solution. The solution provided valuable insights to enable data-driven decision-making and facilitate continuous improvement within the production environment.

Benefits

The implementation of the data-rich real-time analytics dashboard resulted in significant benefits for the manufacturing company. With the solution in place, the client experienced:

Improved Operational Efficiency:

Real-time access to comprehensive data enabled better monitoring and optimization of production processes. Manufacturers could identify bottlenecks, analyze machine performance, and take proactive measures to maximize efficiency and minimize downtime.

Enhanced Decision-Making:

The availability of accurate and up-to-date insights empowered decision-makers to make data-driven decisions in real time. By leveraging the analytics dashboard, manufacturers could align their strategies with real-time trends, anticipate market demands, and optimize resource allocation for improved productivity.

Production Optimization:

Every manufacturing unit needs to optimize production by utilizing all available resources at maximum. By getting insights into throughput and analyzing other important production data points, manufacturers prioritize and implement process improvements.

Connect With Us To Leverage Data For Insights And Intelligence

Crafting Data Success Stories

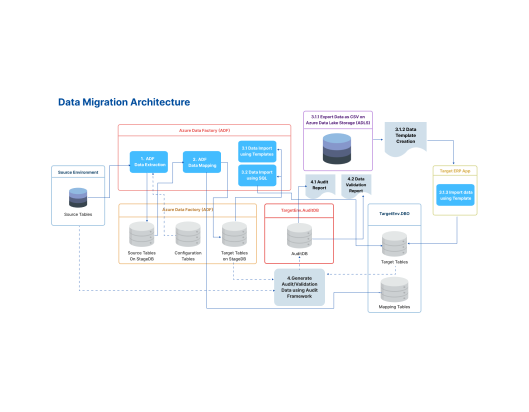

Secure Data Migration Journey For A Leading Construction Company

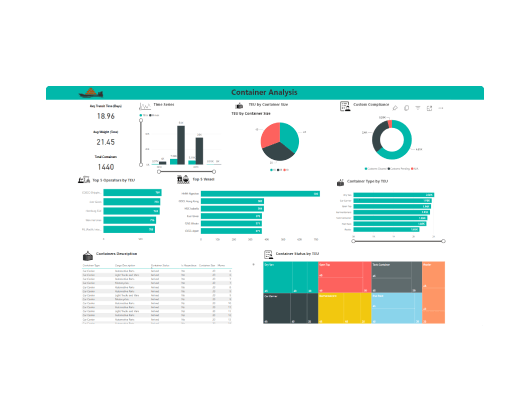

QlikView To Microsoft Power BI Migration

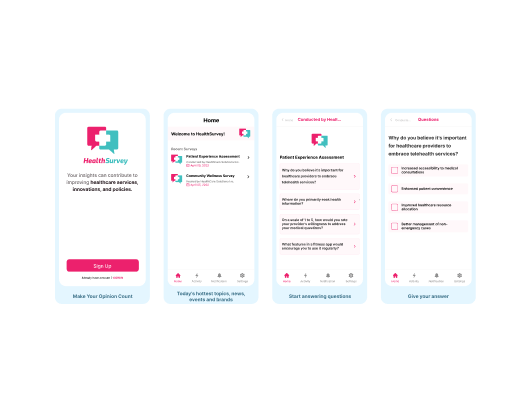

Comprehensive Healthcare Survey Application with Omni-Channel Capabilities

Our Source of Motivation